Shamrock epoxy coatings

Flake - Metallic - Solid Colors

✦

Flake - Metallic - Solid Colors ✦

Shamrock Epoxy Coatings specializes in high-quality epoxy and polyaspartic floor systems designed to transform and protect concrete surfaces. From garage flake floors to custom metallic finishes, we focus on proper surface preparation, premium materials, and clean, efficient installs. Our goal is simple—deliver durable, slip-resistant, and visually stunning floors built to last. Servicing Bucks County and surrounding areas.

Epoxy floor coatings done right…

Decorative Flake

custom Metallic

Solid

Extensive 7 step process….

Step 1: Grind

We begin with diamond tip grinders for thorough concrete preparation, using versatile tooling. This step ensures a strong bond, setting us apart from others. Once done, the concrete is primed for the polyurea base layer.

Step 2: Sealer

We begin with diamond tip grinders for thorough concrete preparation, using versatile tooling. This step ensures a strong bond, setting us apart from others. Once done, the concrete is primed for the polyurea base layer.

Step 3: Repair

We fix cracks, divots, and flaws with a quick-curing polymer, but we advise against filling open expansion joints, leaving them as they are.

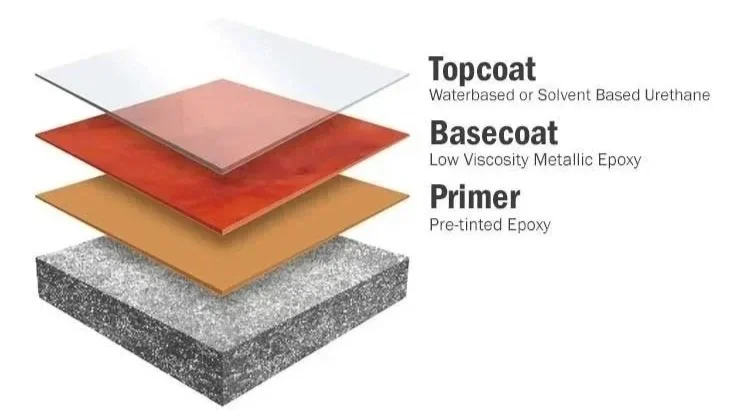

Step 4: Base

We apply a pigmented industrial-grade polyurea base coat for a super-strong bond. It’s four times stronger than regular epoxy, incredibly flexible, and outperforms typical epoxy in adhesion.

Step 5: Flake/Metallic

As the base coat is still wet, we cover the floor with colorful PVC flakes, forming a dynamic pattern. The polyurea base coat bonds with both the concrete and PVC flakes, creating a solid foundation. With over 25 pre-made blends or custom options for a unique look, the choices are limitless.

Step 6: Scrape (If Flake)

After curing, excess flakes are removed to finish with 95-98% coverage due to our initial thick application.

Step 7: Top coat

Top coat goes on in matte, or gloss with an optional added slip-resistant grit to the clear top coat for improved wet surface safety.

– Walk on your floor within 12 hours

– Move heavy items back within 24 hours

– Drive on your floor within 48 hours

FAQs

What type of flooring chemicals do you use?

1

We use ubc epoxy or ple epoxy for base coat depending on circumstances, both have their strengths. For the topcoat, we can use a Polyaspartic or the ple epoxy coating.

I have some cracks and pitting. Can you repair this condition?

2

Generally, yes. We utilize a fast-curing patching system that works extremely well and is compatible with our other chemicals. This approach is used on all pitting, divots and cracks, with several layers being applied if the crack is particularly wide or deep. If you have areas where the concrete has shifted up or down, more extensive repairs may be necessary

Do the chemicals smell during installation?

3

Yes there will be an odor. However it will typically dissipate in a day or two.

Can you just go over my current coating?

4

Unfortunately, that is not generally an option. In most instances we prefer to start with clean base to make sure of best proper adhesion.